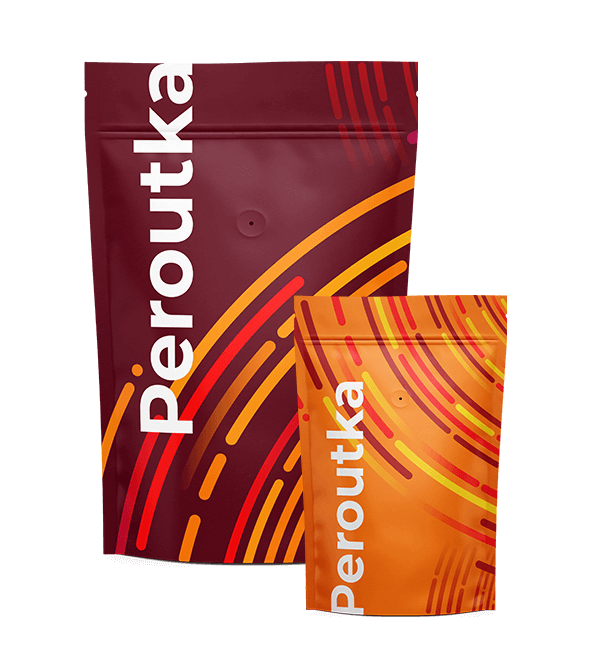

Take a look at our bags and scalculate the production price without obligation using our calculator!

Use

Standing bags have a shaped bottom compared to hanging bags. The bags are designed for both machine and manual filling. Hand-filled bags only need to be sealed with a hand-held foil welder after filling..

The bag can be equipped with a resealable zip and an opening for the Euro hanging system.

We print bags digitally or using flexprint technology according to individual specifications. The surface of the bags can be laminated (with printing underneath the top layer) or uncoated.

The bags are designed for packaging food and other goods. This corresponds with the material composition of the bag.

Specifications

Dimensions and design of stand-up and hanging bags

Bag dimensions and design

The maximum dimensions of the bag are defined based on the material used and with regard to its final treatment - protection of the print by lamination or varnishing:

plastic materials: height 360 mm, width 230 mm.

paper materials: height 305 mm, width 230 mm

The bag may contain a closable zipper, a cutout for a Euro hanger and a tab for easy opening of the bag.

Graphics - printing colors

We print according to the graphic designs you provide. The graphic design can contain images and color shades defined according to the Pantone swatch book. When printing transparent or metallic materials, we base the graphics with white paint.

Since the bags are produced continuously and the last operation is to cut the individual pieces apart, it is advantageous to choose graphics on the edges of the bag that tolerates a cutting inaccuracy of approximately 0.02 mm. The graphics therefore need to be designed in such a way that they do not appear distracting on the edge of the bag, given the aforementioned cutting inaccuracy.

Why choose stand-up pouches?

We supply high and low volumes for limited editions and seasonal production.

Thanks to the unique HP “Pack Ready” technology, we make deliveries in the shortest possible time.

We help our customers to achieve higher sales thanks to high quality and the use of special printing effects.

Almost 30 years of experience combined with our know-how guarantee trouble-free packaging of your products.

We reduce the risk of inventory shrinkage thanks to rapid supplies of prints on request.

Get your original packaging

- We will recommend appropriate size and material

- We will create a graphic design

- Usage of the most adequate printing technology

Your product in our packaging will get attention of all customers.